Our history explained and illustrated

If in 1858 the Trieste businessperson Jurij Gossleth had not bought a ship loaded with chrome ore and saltpetre, thinking that it carried dill, our chemical plant probably would not have existed. Instead, Gossleth, searching for a suitable place to process the cargo, discovered the Hrastnik valley. Everything was at hand: the railway, the coal, clean water and hardworking workers.

Two years later, in 1860, the plant – as the first in the then Habsburg monarchy - was already producing highly sought-after leather tanning products. The company soon became renowned for its products - saltpetre, tanning agents, soda, soaps, and detergents.

In 1870 and 1872, the outlined base chemistry continued, complemented by the production of two kinds of inorganic acids: the sulphuric and the hydrochloric acid. Both acids already had significant market capacities at that time, and in particular, they influenced the further development direction.

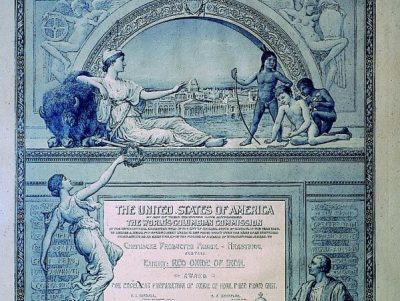

A few years later, in 1894, the company’s products were introduced in the USA, notably the copperas, iron oxide paints and various salts. The company received its first high-level prize, when the iron oxide paint won a gold plaque at the Chicago world fair.

The product range changed as decades passed and owners changed, too. In 1925, the product range was expanded to include the production of water-soluble oils for the leather and textile industries.

In 1931, a plant for the processing of opium alkaloids was built.

The period 1957 – 1962 was dedicated to renovating the plant and brought the then state-of-the-art production plants for the sodium tripolyphosphate and the chlor-alkali electrolysis products. This set the course for the further development of the plant, specializing for the production of the phosphorus salts.

1964: Production of additives for the meat and dairy industry.

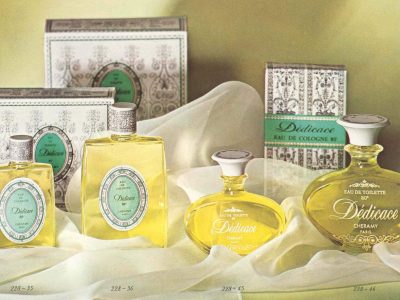

1970: Starting to expand to the field of process chemistry: producing decorative cosmetics and perfumery in cooperation with French and subsequently Italian partners.

1985 – Production start of the powdered laundry detergents, as well as household and industrial cleaning products.

In 1996, a modern, environmentally friendly chlor-alkali electrolysis plant, using the membrane process technology, was built.

In 2002, an important acquisition was made: a new spray tower used for the production of sodium and potassium tripolyphosphates.

In 2003, we started the production of calcium phosphates in the phosphates profit centre, the products being used as a mineral additive in the preparation of various feeds for cattle, pigs, poultry and other animals.

In the same year, we started a new production plant in the general consumption profit centre, consisting of a mixing system and a filling line, producing liquid detergents and cleaning products.

In 2006, the phosphate production became less ecologically harmful and more technologically advanced. The entire production takes place within a closed cycle in which all water (for cooling and technological purposes) is returned to the process. The purification of the phosphoric acid is carried out by solvent extraction, where the raffinate is used in the production of the calcium phosphates. In the plant itself, we installed two separate systems of bag filters to reduce dust particles.

In 2008, we replaced the DD 350 type electrolysers with the new BM 2.7 type in the chlor-alkali electrolysis profit centre. The state-of-the art elements in this electrolyser belong to the fourth generation and are more advanced than the previous ones in all of the important aspects, including energy efficiency, lifespan and the design solution.

In 2010, the phosphate profit centre started the production of food grade calcium phosphates, which are used in the food industry, pharmacy and other fields.

In 2014, the phosphates profit centre obtained a new acquisition: a modern, automatic filling phosphate packaging machine.

In 2015, we obtained the FAMI QS certificate, which facilitates the marketing of feed grade phosphates.

The general consumption profit centre invested in a packaging machine for powdered detergents and a new line for filling the liquid cleaning products and detergents into smaller packages.

In 2016, the utility and industrial wastewater from our plant was connected to the sewage collector and wastewater treatment plant in Hrastnik.

In the same year, we obtained the environmental permit for a higher risk plant, the Seveso.

Installation of a new steam boiler for the TKI company.

We obtained the IFS certificate for the phosphate plant and set up a granulated phosphate device.

We successfully registered our biocidal products and harmonised our permit with the BAT and BREF requirements.

TKI Hrastnik, d.d. is awarded the environmental standard ISO 14001.

We successfully changed the plant's electricity supply from 35 kV to 20 kV and set up the production of premixes and lick blocks.

TKI Hrastnik, d.d. is awarded the standard ISO 50001.

Installation of a 664 kW solar power plant on the company's premises.